In an effort to cut expenses, GHI, Inc. moves responsibility for logistics to the supply management department. Some officers in the firm are skeptical that this move will be beneficial, since most shipping providers use published rates, and there will be little room for cost improvement. Which of the following will be the BEST way for GHTs supply manager to demonstrate that supply management skills can obtain better value in shipping?

A supply manager is responsible for the raw material supply to a manufacturing operation. After three months of successfully meeting key performance indicators (KPIs), the supply manager conducts a meeting with stakeholders—including engineers, manufacturing technicians, supply chain personnel, and finance team members—to solicit their feedback regarding the raw material supply chain. Which of the following quality management principles is the supply manager executing?

For many years, WXY Company's policy has been to buy only domestically manufactured MRO materials and maintain quantities of these materials at each operating location. A recent analysis reveals that this practice is not the most efficient and effective way for this firm to manage its MRO purchases. Given this situation, which of the following is the BEST course of action for WXY’s supply management department to take?

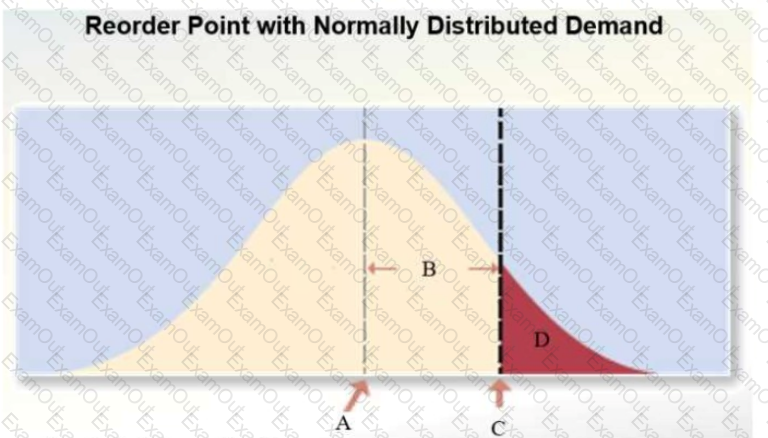

A firm sells an average of 2,000 units of snacks from its existing stock while it waits for orders to be delivered. Demand during lead time varies in accordance with a normal distribution. The firm's supply manager prepares a presentation to explain the concept of customer service and safety stock levels using the following figure:

What does the shaded area D (in red) represent?

PQR, Inc. produces office supplies for big box retailers. This is a highly competitive market and the requirement for maintaining a continuous inventory of product for retailers is a high priority for PQR. Recently, the firm experienced shipping delays from overseas suppliers. Which of the costs associated with shortages would be MOST critical for PQR?

A utility installation company conducts an annual review of its assets. Included with its equipment are several trenching machines that were purchased three years ago at a cost of $85,000 each. How should this value be categorized in the asset management system?

A supply manager is reviewing safety stock for a particular unit. The unit is small, Inexpensive, non-perishable, and easily stored, but is critical to the firm's manufacturing process. The following information is known about this unit:

Maximum lead time = 8 Days

Average lead time = 3 Days

Maximum daily usage = 6,000 Units

Average daily usage = 4,000 Units

What is the maximum safety stock that should be maintained for this unit?

A firm collects the following forecasted and actual demand for a certain part:

PeriodForecastActual

KI30311

22531

32826

42520

What is the absolute value of the forecast error?

A large retailer and one of its suppliers establish a process to combine intelligence from both organizations in order to improve product availability while reducing inventory, transportation, and logistics costs. This process is known as which of the following?

A company that manufactures rubber balls wishes to discontinue production and move into the golf ball industry. Consider the following steps in the disposition of the current inventory of rubber balls:

I. Dispose of the rubber balls per local regulations

II. Sell the rubber balls on the open market

III. Grind up the rubber balls and donate the material for a playground in the community

IV. Work with engineering to determine if the rubber can be used in the new golf ball line

In order to maximize recovery of its investment, which of the following is the BEST order for the application of these steps (from first to last)?