Which of the following distinguishes risk from uncertainty?

A company is considering whether to develop an overseas market for its products. The cost of developing the new market is estimated to be $250,000. There is a 70% probability that the development of the new market will succeed and a 30% probability that the development of the new market will fail and no further expenditure will be incurred.

If the market development is successful, the profit from the new market will depend on prevailing exchange rates. There is a 50% chance that exchange rates will be in line with expectations and a profit of $500,000 will be made. There is a 20% chance that exchange rates will be favorable and a profit of $630,000 will be made and a 30% chance that exchange rates will be adverse and a profit of $100,000 will be made.

The profit figures stated are before taking account of the development costs of $250,000.

Use a decision tree to decide whether the company should develop an overseas market for its products.

Select one correct answer.

According to a decision tree forecasting, there are three possible outcomes of a project requiring £10,000 capital investment. They are (along with probability of occurring): £20,000 in revenue (45%), £35,000 (15%),

£10,000 (30%) and -£6,000 (10%).

However, choosing another project (2) requiring the same investment would give us £12,000 and choosing project 3 would give us a 90% chance of generating revenues of £15,000 but a 5% chance of revenues of £0.

Project 4 is wildly ambitious and boasts an unlikely (5% chance) of generating revenues of £100,000. There is a 10% probability of negative revenues.

Which is the risk averse investor more likely to take?

Project 1

Project 2

Project 3

Project 4

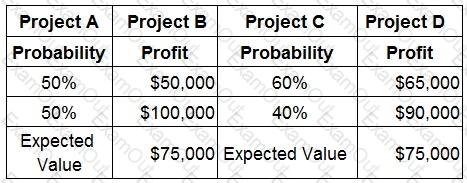

A manager has to decide between four mutually exclusive projects, A, B, C and D:

Using the above information, which Project would a risk seeking manager choose?

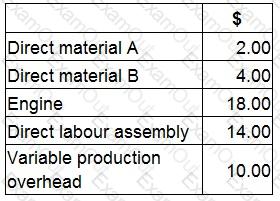

A company manufactures a machine. The machine is made from two types of raw material and is assembled in a factory using skilled labour. The engine for the machine is purchased from an outside supplier.

The following costs relate to the manufacture of one machine:

What is the finished goods inventory valuation for one machine using throughput costing?

CDF is a manufacturing company within the DF group. CDF has been asked to provide a quotation for a contract for a new customer and is aware that this could lead to further orders. As a consequence, CDF will produce the quotation by using relevant costing instead of its usual method of full cost plus pricing. The following information has been obtained in relation to the contract: Material D 40 tons of material D would be required. This material is in regular use by CDF and has a current purchase price of $38 per ton. Currently, there are 5 tons in inventory which cost $35 per ton. The resale value of the material in inventory is $24 per ton.

Components 4,000 components would be required. These could be bought externally for $15 each or alternatively they could be supplied by RDF, another company within the DF manufacturing group. The variable cost of the component if it were manufactured by RDF would be $8 per unit, and RDF adds 30% to its variable cost to contribute to its fixed costs plus a further 20% to this total cost in order to set its internal transfer price. RDF has sufficient capacity to produce 2,500 components without affecting its ability to satisfy its own external customers. However, in order to make the extra 1,500 components required by CDF, RDF would have to forgo other external sales of $50,000 which have a contribution to sales ratio of 40%.

Labour hours 850 direct labour hours would be required. All direct labour within CDF is paid on an hourly basis with no guaranteed wage agreement. The grade of labour required is currently paid $10 per hour, but department W is already working at 100% capacity. Possible ways of overcoming this problem are: • Use workers in department Z, because it has sufficient capacity. These workers are paid $15 per hour. • Arrange for sub-contract workers to undertake some of the other work that is performed in department W. The sub-contract workers would cost $13 per hour.

Specialist machine The contract would require a specialist machine. The machine could be hired for $15,000 or it could be bought for $50,000. At the end of the contract if the machine were bought, it could be sold for $30,000. Alternatively, it could be modified at a cost of $5,000 and then used on other contracts instead of buying another essential machine that would cost $45,000. The operating costs of the machine are payable by CDF whether it hires or buys the machine. These costs would total $12,000 in respect of the new contract.

Supervisor The contract would be supervised by an existing manager who is paid an annual salary of $50,000 and has sufficient capacity to carry out this supervision. The manager would receive a bonus of $500 for the additional work.

Development time 15 hours of development time at a cost of $3,000 have already been worked in determining the resource requirements of the contract.

Fixed overhead absorption rate CDF uses an absorption rate of $20 per direct labour hour to recover its general fixed overhead costs. This includes $5 per hour for depreciation.

Calculate the relevant cost of the contract to CDF. You must present your answer in a schedule that clearly shows the relevant cost value for each of the items identified above. You should also explain each relevant cost value you have included in your schedule and why any values you have excluded are not relevant.

Ignore taxation and the time value of money.

Select all the true statements.

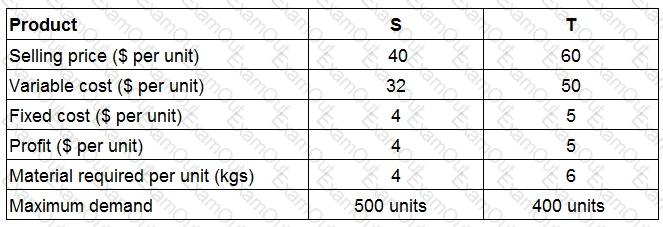

Two products being produced by a company require the same material which is limited to 2,600 kgs.

What is the optimal production plan?

The labour requirement for a special contract is 250 skilled labour hours paid at $10 per hour and 750 semi-skilled labour hours paid at $8 per hour.

At present, skilled labour is fully utilised on other contracts which generate a $12 contribution per hour, after charging labour costs. Additional skilled labour is unavailable in the short term.

There is a surplus of 1,200 semi-skilled hours over the period of the contract but the firm has a policy of no redundancies.

The relevant cost of labour for the special contract is:

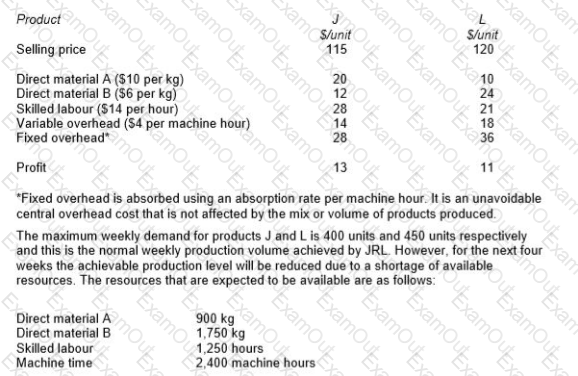

JRL manufactures two products from different combinations of the same resources. Unit selling prices and unit cost details for each product are as follows:

Identify, using graphical linear programming, the weekly production schedule for products J and L that will maximize the profits of JRL during the next four weeks.

The definition of a trend is: